Hi all,

For the past two months or so I've been working on several knives for some friends, which would be the first functional knives I've made for people other than myself . It was (is) quite a journey and I learned lots on the way, making multiple pieces at once was more daunting than I had originally thought but it was fun all round. As I still consider myself a learner and didn't want to invest in shipping off my knives to heat treat, I opted to make all of them (save for one) from 1/8" O1 tool steel.

The first two knives I worked on were a cheese knife and a leaf bladed camp knife. Everything was going well up to grinding in the bevels as I was a little too eager with the grinder and ended up getting the bevels too thin while trying to get the flat grind to reach full height, which I had learned the hard way. Upon heat treating and quenching, the edges of the blades ended up looking like a piece of curly lettuce due to the lack of material to provide stability. Needless to say, I couldn't send these knives out the door, but they were still salvageable, but they're now completely unrecognizable as I needed to grind out the warping, and the cheese knife now will live it's life as a very overbuilt marking scribe and shop utility blade and the camp knife is now a very funky looking skinning knife (will post pics of those if people are interested).

|

| Note that the edge is extremely thin - roughly 0.3 mm at most. |

So it was back to the drawing board with those blades, and I ground those ones to be roughly 0.5 mm on the cheese knife and 1 mm on the camp knife as it would benefit from having the extra meat behind the edge and blended the spots where flat grind didn't reach. Heat treating this time was a success, it's surprising how much of a difference those tiny differences in thickness make in the final outcome, and allowed me to have more room for grinding off any decarb that may have formed.

|

| So far so good - the drill press vise and blocks under the knives were used to bend the camp knife to true since it did get a bit of a bend in the blade - probably due to stresses that were in the flat bar. |

|

| The edges look a bit thick now, but after sanding off the decarb they lost about 0.25 mm, bringing them to a good thickness for putting a cutting edge. |

A small thing that I found with both knives though was that I still had the bad habit of grinding into the spine trying to chase the plunge lines so that they were even. While I did do this with my last knife ( the city knife) to thin out the stock, in these types of knives, this kind of mistake would be viewed as amateurish and would detract from the value of the blade, although in my opinion with respect to function there would be negligible difference in performance. This was due in part to my grinder speed being far too fast (3400 RPM, over double of what I'd like) and having a lop sided work rest that can't be corrected, and a makeshift platen, that made grinding at a consistent angle fairly difficult even when using a jig. Some may argue that I can get around this by just knowing where the skew is and grinding freehand without the work rest. While I respect those who are able to do that, the skew seems to change every time I switch belts, and a jig would a) greatly increase the speed at which I grind b) allow for consistency between knives. I am now in the process of upgrading to a real knife making grinder that I'm looking forward to very much and should allow me to do most of the heavy work. Since everything will be square I'll be able to change the speed of the grinder so that I could really dial in the grinds. In the meantime, in order to get around this problem in the meantime I realized that I'd have to deal with the plunges by hand, which is fairly time consuming, but would allow me to the flat grind just to the spine without grinding into it and compromising the look of the blade.

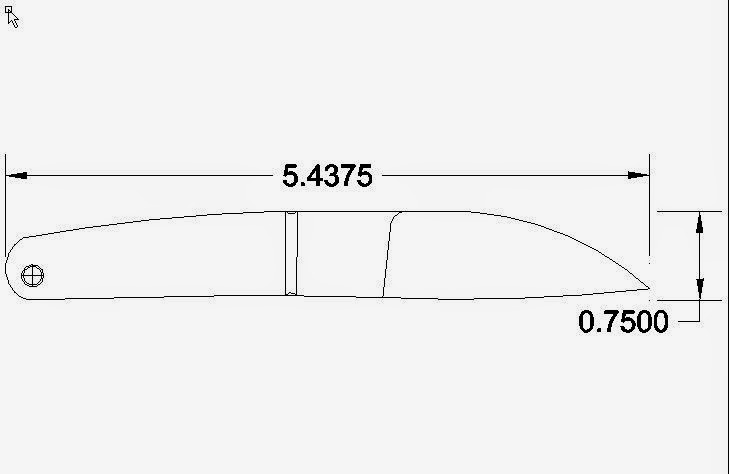

This was what I did for the third blade, a pocket fixed blade, which is probably the cleanest ground knife I've done to date. I forgot to take a picture of it before I taped it up for putting a handle on it (so you'll have to take my word for it, haha). The fourth knife I worked on was a nessmuk that I had ground out about 2 years ago but didn't have the will power to finish until a friend of mine expressed interest in the design. Nothing exciting going on with that one, it was a fairly beefy blade (0.25" thick) so there were no issues with the heat treatment and only needed the handle to be profiled down to a more reasonable size, since it was one of my earlier designs where I was still learning how to make ergonomic handles. Had I left it, the handle probably would have only been good for Andre the Giant.

|

| pocket fixed blade - in the process of having holes drilled in for hardware |

|

| nessmuk (before holes were drilled) |

After heat treating everything cleaning up the blades, I started on the handle materials. By far the easiest knife to prepare a handle for was the camp knife, as I was using natural canvas micarta for the handle that didn't need any special preparation since it was already flat. For the cheese knife, my friend wanted a unique handle material that was made from a recycled material that stood out and caught the eye, so I settled on using denimite, a composite material made from shredded jeans and 0-VOC resin. The one mistake I made while ordering the material was not specifying that they sand the faces of the material, so to my surprise they came fairly rough and bumpy, and while a very unique looking material, was still annoying to sand. Although it did add extra work, this was not too much of an issue as I was already going to be truing up handle materials for the other two knives since my friends requested cocobolo for those ones, which I cut from turning stock. For people who are making interested in making their own handle scales, unless you have a disk sander and a steady hand , band saw, or some other power equipment, be prepared for constant going back and forth with sanding and checking, and an obscene amount of dust and have a good dust collection system - I needed to change out fresh particulate filters on my dust mask after I was through with all of the scales (it probably means I need a better dust collection system though if anything haha). In the future I'll probably be sticking to pre-sanded materials whenever I can so save myself the trouble.

After that it was just a matter of epoxying on the scale liners and drilling the holes. Following that it'll be gluing and shaping the handles, then making the sheaths, which in itself is easily it's own project. More to come soon!

|

| Gluing up the scales with 2 part epoxy after scuffing all liners and handle scales with 36 grit abrasive. To make my life easier I flattened the bottom of several chunks of 2x4 and lined them and the base ( marble slab) with waxed paper so that I could save on clamps while getting even pressure over multiple pieces at once. Some mistakes I made in my previous knife with a lined handle was not using enough epoxy, over clamping the scales, and not roughing them up enough, resulting in too much squeeze out of what little epoxy there was. Over time the liners began to move over time since they didn't have enough epoxy holding them together to the blade and scale, but given how I did the scales up this time this shouldn't be a problem. |

|

| Drilling holes for hardware - for the wood materials I placed a sacrificial piece of mdf beneath the scale to prevent tear out, which turned out pretty nicely. |

|

| Handle scales test fitted and rough cut to fit the knives. The camp knife and nessmuk were left uncut since I would need to cut those ones outside due to the use of micarta in the scales/ liners. Those materials need a very well ventilated area to be worked since they give off formaldehyde when worked (i.e. I'll need to do it in the garage). While drilling I improvised a dust collection system with the shop vac and vented out the exhaust to outside, but this would not work for steps where more dust was generated. |